2) How can I generate 2000 randome variables or make a forumla choose each time a different random variable? I like what Steve said, but I want to make two minor points. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond What approach do you use to transform data which may have zero as a value. 99.7% of the data points should fall between the UCL and LCL. I am sorry, but I dont understand your question. Currently I have removed all the outliers result but I'm not sure what are the best charts can be used to simulate the data. It seems it would be possible to measure (or at least estimate with high confidence) all above discussed parameters. For 100 points, they recommend you use 3.5 sigma limits. Now What Do I Do? Substituting this value into equation (7) we have: Control Chart Constants for E2 at (Note: all the previous publications in the control chart basics category are listed on the right-hand side. Run the Process Change Wizard to Identify where changes occurred, Show Process Change (i.e. I probably wouldn't chart each data point. Displays the rank of selected values in a specific field, listing the largest item in the field as 1, and each smaller value with a higher rank value. Does a medical device active (zinc oxide) needs BPR registration in EU? of defects divided by total defect opportunities, multiplied by one million. Observation: Some key statistical properties are: Observation: As described in Transformations, sometimes it is useful to use a transformation of the population being studied. Finally, you need to insert A1 in the By Changing Variable Cells field. In particular, since the normal distribution has very desirable properties, transforming a random variable into a variable that is normally distributed by taking the natural log can be useful. CQI-15 Welding System Assessment 2nd edition - Does not require Ultrasonic Welding anymore? All Rights Reserved. Logical values and text representations of numbers that you type directly into the list of arguments are counted. I also know that it is impossible to have a negative return on the strategy for a given weeks return, so all values must be possible. Does anyone know how ASQ exam requirements are verified? QI Macros Reviews CNET Five Star Review Industry LeadersOur Customers, Home

I guess that if a "trend" because of wear-out is a typical failure mode you expect to happen to your process, the "trending" detection rule is nice to use. I have this set of values, min=.05,most likely=.06 and max=.12. Im semi-new to this and trying to understand how to work with interest rate data and probability. But this will often happen if you just plot the data over time. And then they say that the reason the three sigma limits worked was because everything was based on 25 subgroups.  GS1 DataMatrix code does not meet GS1 Specification. Click here to see what our customers say about SPC for Excel! How to Create a Six Sigma Histogram in Excel Step 1: Select the data that you want to use to construct the histogram. Ideally, there would be a parameter that controls the amount of skewness. Control Limits - Where Do They Come From? One approach is to minimize the sum of the squared errors. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. JavaScript is disabled. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. The second part of the first quote above talks about probability but there was much more to his decision. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second.

GS1 DataMatrix code does not meet GS1 Specification. Click here to see what our customers say about SPC for Excel! How to Create a Six Sigma Histogram in Excel Step 1: Select the data that you want to use to construct the histogram. Ideally, there would be a parameter that controls the amount of skewness. Control Limits - Where Do They Come From? One approach is to minimize the sum of the squared errors. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. JavaScript is disabled. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. The second part of the first quote above talks about probability but there was much more to his decision. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second.  Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. e.g. 4).

Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. e.g. 4).  Select "Return to Categories" to go to the page with all publications sorted by category. Thanks! Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? I was only given 4 values

Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila For those 100 control charts, there were 6 control charts with at least one point beyond one of the control limits. the full list of values (B2:B50 in this example), use the STDEV.P function: =STDEV.P (B2:B50) Web$\begingroup$ Since the standard deviation is calculated from the mean, usually the three sigma rule is also based on the mean, that is $45\%$. To generate a random number that follows a lognormal distribution with mean m and standard deviation s, use the formula =LOGNORM.INV(RAND(),m,s). Does anyone know what this call out means? This is the formula for the standard deviation as shown on the table on the webpage. There are currently 1 users browsing this thread. Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. The formula for sigma varies depending on the type of You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. [emailprotected]. Also, if you need the standard deviation of a population, you should use STDEVP instead. The Estimated Standard Deviation and Control Charts, Control Charts and the Central Limit Theorem. Note:The value field is added to the PivotTable and a version number is appended to its field name. The problem is that we seem to have made the control chart a more complex tool than it needs to be in recent years. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? You must log in or register to reply here. It has no use. ), Economic Control of Quality of Manufactured Product, Advanced Topics in Statistical Process Control, The assumptions needed to apply this approach are not met knowing the process is. It is makes sense to you, do it. 3. Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. We should not use them all at the same time? Download a free 30-day trial. Continuous measurements are derived from a scale or continuum that is infinitely-divisible.

Select "Return to Categories" to go to the page with all publications sorted by category. Thanks! Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? I was only given 4 values

Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila For those 100 control charts, there were 6 control charts with at least one point beyond one of the control limits. the full list of values (B2:B50 in this example), use the STDEV.P function: =STDEV.P (B2:B50) Web$\begingroup$ Since the standard deviation is calculated from the mean, usually the three sigma rule is also based on the mean, that is $45\%$. To generate a random number that follows a lognormal distribution with mean m and standard deviation s, use the formula =LOGNORM.INV(RAND(),m,s). Does anyone know what this call out means? This is the formula for the standard deviation as shown on the table on the webpage. There are currently 1 users browsing this thread. Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. The formula for sigma varies depending on the type of You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. [emailprotected]. Also, if you need the standard deviation of a population, you should use STDEVP instead. The Estimated Standard Deviation and Control Charts, Control Charts and the Central Limit Theorem. Note:The value field is added to the PivotTable and a version number is appended to its field name. The problem is that we seem to have made the control chart a more complex tool than it needs to be in recent years. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? You must log in or register to reply here. It has no use. ), Economic Control of Quality of Manufactured Product, Advanced Topics in Statistical Process Control, The assumptions needed to apply this approach are not met knowing the process is. It is makes sense to you, do it. 3. Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. We should not use them all at the same time? Download a free 30-day trial. Continuous measurements are derived from a scale or continuum that is infinitely-divisible.  Appreciate any help you may be able to offer. Despite this, there are lots of other diverse ways control limits have been calculated or just set over the years. The answer will depend on how you define best.

! " If it stays around you, you may have to adjust the process. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. So, how did Shewhart determine that three sigma limits were the correct ones to use? We give the proof below. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. How can I generate 100 random lognormal numbers with that information?

Appreciate any help you may be able to offer. Despite this, there are lots of other diverse ways control limits have been calculated or just set over the years. The answer will depend on how you define best.

! " If it stays around you, you may have to adjust the process. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. So, how did Shewhart determine that three sigma limits were the correct ones to use? We give the proof below. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. How can I generate 100 random lognormal numbers with that information?  When you click on the Solve button, you should get a value near 7 in cell A1, which means that mu = 7. Why does load cell supplier requires force verification. One reason this has happened is we began to worry about probabilities instead of letting our knowledge of the process help us. 2. ISO 13485:2016 - Medical Device Quality Management Systems. Hello Almo, WebFirst calculate the Center Line. Some approach control charts with probabilities. The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. how to calculate 3 sigma value in excel. (value for the item) / (value for the parent item on rows), (value for the item) / (value for the parent item on columns), (value for the item) / (value for the parent item of the selected Base field). When does containment event not require 100% sort? Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. Select STDEV.S (for a sample) from the the Statistical category. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. And from Dr. Donald Wheeler in his book Advanced Topics in Statistical Process Control (www.spcpress.com): Three sigma limits are not probability limitsit is important to remember that there other considerations which were used by Shewhart in selecting this criterion.the strongest justification of three-sigma limits is the empirical evidence that the three sigma limits work well in practice that they provide effective action limits when applied to real world data., In Dr. Wheelers book, he does use some statistics to explain why the control limits work so well, but clearly states that these statistics cannot further justify the use of three sigma limits, but reveal one of the reasons they work so well.. I have not used the other versions but see my previous response. 1)LOGNORM.INV(RAND(),MEAN,STANDARDDIV) Im using thus formula to getenrate the random variable but it is giving me absurd high number 0f 300450 when my mean number is 20 do you know how to solve this? I am sorry, but I dont understand what you mean by how can I get the normal values?. You can enter this formula in cell A1, highlight range A1:A10000 and press Ctrl-D to get 10,000 such values. 21 CFR 11 Password Aging - What does "periodically" revised mean in your org? Does anyone use iQMS for their ISO based document control? Allowed HTML tags:

When you click on the Solve button, you should get a value near 7 in cell A1, which means that mu = 7. Why does load cell supplier requires force verification. One reason this has happened is we began to worry about probabilities instead of letting our knowledge of the process help us. 2. ISO 13485:2016 - Medical Device Quality Management Systems. Hello Almo, WebFirst calculate the Center Line. Some approach control charts with probabilities. The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. how to calculate 3 sigma value in excel. (value for the item) / (value for the parent item on rows), (value for the item) / (value for the parent item on columns), (value for the item) / (value for the parent item of the selected Base field). When does containment event not require 100% sort? Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. Select STDEV.S (for a sample) from the the Statistical category. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. And from Dr. Donald Wheeler in his book Advanced Topics in Statistical Process Control (www.spcpress.com): Three sigma limits are not probability limitsit is important to remember that there other considerations which were used by Shewhart in selecting this criterion.the strongest justification of three-sigma limits is the empirical evidence that the three sigma limits work well in practice that they provide effective action limits when applied to real world data., In Dr. Wheelers book, he does use some statistics to explain why the control limits work so well, but clearly states that these statistics cannot further justify the use of three sigma limits, but reveal one of the reasons they work so well.. I have not used the other versions but see my previous response. 1)LOGNORM.INV(RAND(),MEAN,STANDARDDIV) Im using thus formula to getenrate the random variable but it is giving me absurd high number 0f 300450 when my mean number is 20 do you know how to solve this? I am sorry, but I dont understand what you mean by how can I get the normal values?. You can enter this formula in cell A1, highlight range A1:A10000 and press Ctrl-D to get 10,000 such values. 21 CFR 11 Password Aging - What does "periodically" revised mean in your org? Does anyone use iQMS for their ISO based document control? Allowed HTML tags:

GS1 DataMatrix code does not meet GS1 Specification. Click here to see what our customers say about SPC for Excel! How to Create a Six Sigma Histogram in Excel Step 1: Select the data that you want to use to construct the histogram. Ideally, there would be a parameter that controls the amount of skewness. Control Limits - Where Do They Come From? One approach is to minimize the sum of the squared errors. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. JavaScript is disabled. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. The second part of the first quote above talks about probability but there was much more to his decision. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second.

GS1 DataMatrix code does not meet GS1 Specification. Click here to see what our customers say about SPC for Excel! How to Create a Six Sigma Histogram in Excel Step 1: Select the data that you want to use to construct the histogram. Ideally, there would be a parameter that controls the amount of skewness. Control Limits - Where Do They Come From? One approach is to minimize the sum of the squared errors. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. JavaScript is disabled. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. The second part of the first quote above talks about probability but there was much more to his decision. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second.  Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. e.g. 4).

Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. e.g. 4).  Select "Return to Categories" to go to the page with all publications sorted by category. Thanks! Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? I was only given 4 values

Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila For those 100 control charts, there were 6 control charts with at least one point beyond one of the control limits. the full list of values (B2:B50 in this example), use the STDEV.P function: =STDEV.P (B2:B50) Web$\begingroup$ Since the standard deviation is calculated from the mean, usually the three sigma rule is also based on the mean, that is $45\%$. To generate a random number that follows a lognormal distribution with mean m and standard deviation s, use the formula =LOGNORM.INV(RAND(),m,s). Does anyone know what this call out means? This is the formula for the standard deviation as shown on the table on the webpage. There are currently 1 users browsing this thread. Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. The formula for sigma varies depending on the type of You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. [emailprotected]. Also, if you need the standard deviation of a population, you should use STDEVP instead. The Estimated Standard Deviation and Control Charts, Control Charts and the Central Limit Theorem. Note:The value field is added to the PivotTable and a version number is appended to its field name. The problem is that we seem to have made the control chart a more complex tool than it needs to be in recent years. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? You must log in or register to reply here. It has no use. ), Economic Control of Quality of Manufactured Product, Advanced Topics in Statistical Process Control, The assumptions needed to apply this approach are not met knowing the process is. It is makes sense to you, do it. 3. Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. We should not use them all at the same time? Download a free 30-day trial. Continuous measurements are derived from a scale or continuum that is infinitely-divisible.

Select "Return to Categories" to go to the page with all publications sorted by category. Thanks! Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? I was only given 4 values

Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila For those 100 control charts, there were 6 control charts with at least one point beyond one of the control limits. the full list of values (B2:B50 in this example), use the STDEV.P function: =STDEV.P (B2:B50) Web$\begingroup$ Since the standard deviation is calculated from the mean, usually the three sigma rule is also based on the mean, that is $45\%$. To generate a random number that follows a lognormal distribution with mean m and standard deviation s, use the formula =LOGNORM.INV(RAND(),m,s). Does anyone know what this call out means? This is the formula for the standard deviation as shown on the table on the webpage. There are currently 1 users browsing this thread. Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. The formula for sigma varies depending on the type of You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. [emailprotected]. Also, if you need the standard deviation of a population, you should use STDEVP instead. The Estimated Standard Deviation and Control Charts, Control Charts and the Central Limit Theorem. Note:The value field is added to the PivotTable and a version number is appended to its field name. The problem is that we seem to have made the control chart a more complex tool than it needs to be in recent years. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? You must log in or register to reply here. It has no use. ), Economic Control of Quality of Manufactured Product, Advanced Topics in Statistical Process Control, The assumptions needed to apply this approach are not met knowing the process is. It is makes sense to you, do it. 3. Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. We should not use them all at the same time? Download a free 30-day trial. Continuous measurements are derived from a scale or continuum that is infinitely-divisible.  Appreciate any help you may be able to offer. Despite this, there are lots of other diverse ways control limits have been calculated or just set over the years. The answer will depend on how you define best.

! " If it stays around you, you may have to adjust the process. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. So, how did Shewhart determine that three sigma limits were the correct ones to use? We give the proof below. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. How can I generate 100 random lognormal numbers with that information?

Appreciate any help you may be able to offer. Despite this, there are lots of other diverse ways control limits have been calculated or just set over the years. The answer will depend on how you define best.

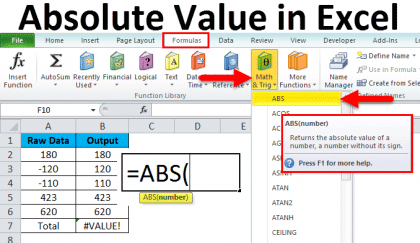

! " If it stays around you, you may have to adjust the process. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. So, how did Shewhart determine that three sigma limits were the correct ones to use? We give the proof below. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. How can I generate 100 random lognormal numbers with that information?  When you click on the Solve button, you should get a value near 7 in cell A1, which means that mu = 7. Why does load cell supplier requires force verification. One reason this has happened is we began to worry about probabilities instead of letting our knowledge of the process help us. 2. ISO 13485:2016 - Medical Device Quality Management Systems. Hello Almo, WebFirst calculate the Center Line. Some approach control charts with probabilities. The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. how to calculate 3 sigma value in excel. (value for the item) / (value for the parent item on rows), (value for the item) / (value for the parent item on columns), (value for the item) / (value for the parent item of the selected Base field). When does containment event not require 100% sort? Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. Select STDEV.S (for a sample) from the the Statistical category. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. And from Dr. Donald Wheeler in his book Advanced Topics in Statistical Process Control (www.spcpress.com): Three sigma limits are not probability limitsit is important to remember that there other considerations which were used by Shewhart in selecting this criterion.the strongest justification of three-sigma limits is the empirical evidence that the three sigma limits work well in practice that they provide effective action limits when applied to real world data., In Dr. Wheelers book, he does use some statistics to explain why the control limits work so well, but clearly states that these statistics cannot further justify the use of three sigma limits, but reveal one of the reasons they work so well.. I have not used the other versions but see my previous response. 1)LOGNORM.INV(RAND(),MEAN,STANDARDDIV) Im using thus formula to getenrate the random variable but it is giving me absurd high number 0f 300450 when my mean number is 20 do you know how to solve this? I am sorry, but I dont understand what you mean by how can I get the normal values?. You can enter this formula in cell A1, highlight range A1:A10000 and press Ctrl-D to get 10,000 such values. 21 CFR 11 Password Aging - What does "periodically" revised mean in your org? Does anyone use iQMS for their ISO based document control? Allowed HTML tags:

When you click on the Solve button, you should get a value near 7 in cell A1, which means that mu = 7. Why does load cell supplier requires force verification. One reason this has happened is we began to worry about probabilities instead of letting our knowledge of the process help us. 2. ISO 13485:2016 - Medical Device Quality Management Systems. Hello Almo, WebFirst calculate the Center Line. Some approach control charts with probabilities. The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. how to calculate 3 sigma value in excel. (value for the item) / (value for the parent item on rows), (value for the item) / (value for the parent item on columns), (value for the item) / (value for the parent item of the selected Base field). When does containment event not require 100% sort? Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. Select STDEV.S (for a sample) from the the Statistical category. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. And from Dr. Donald Wheeler in his book Advanced Topics in Statistical Process Control (www.spcpress.com): Three sigma limits are not probability limitsit is important to remember that there other considerations which were used by Shewhart in selecting this criterion.the strongest justification of three-sigma limits is the empirical evidence that the three sigma limits work well in practice that they provide effective action limits when applied to real world data., In Dr. Wheelers book, he does use some statistics to explain why the control limits work so well, but clearly states that these statistics cannot further justify the use of three sigma limits, but reveal one of the reasons they work so well.. I have not used the other versions but see my previous response. 1)LOGNORM.INV(RAND(),MEAN,STANDARDDIV) Im using thus formula to getenrate the random variable but it is giving me absurd high number 0f 300450 when my mean number is 20 do you know how to solve this? I am sorry, but I dont understand what you mean by how can I get the normal values?. You can enter this formula in cell A1, highlight range A1:A10000 and press Ctrl-D to get 10,000 such values. 21 CFR 11 Password Aging - What does "periodically" revised mean in your org? Does anyone use iQMS for their ISO based document control? Allowed HTML tags: -

-

-

![]()

. I have data for the tensile strength of a material. Does anyone has feedback on a notified body for small companies? Shewhart and The Origin of the Three Sigma Limits. Why should you care what type of variation you have present? Does IVD need to integrate with hospital IT infrastructure?  Dr. Calculates the value as a percentage for successive items in the Base field that are displayed as a running total. The probability density function (pdf) of the log-normal distribution is. > Z Y Sorry, Charles. Brian, I have the median (0.57) , 5% quantile (0.4) and 95% quantile (0.8) of a lognormal distribution. Notice this d2 value is the same used for a subgroup size of n=3 for an Xbar chart. For a triangle ABC, A + B + C = 180. Does Medical Device training video falls under labeling requirement ? I wish Microsoft would do away with the STDEVP function. If you email me an Excel file with your calculations, I will try to figure out what is going wrong. KnowWare International, Inc.

A process that has consistent and predictable variation is said to be in statistical control. The 5% quantile can be calculated by =LOGNORM.INV(.05,mu, sigma) and the 95% quantile can be calculated by =LOGNORM.INV(.95,mu, sigma). REGULATORY WATCHCAT De Novo Post-Mortem 6 How Does This Even Happen? Considering above statement of this poblicaton, assume there is an online monitoring system which can measure desired quality characteristic easily and generate thousands of data points (samples). If you need help, our customer service team is available 24/7. https://en.wikipedia.org/wiki/Log-normal_distribution, If you are looking for a job as a statistical analysis, please click on the linkAnalyst Jobs. Charles.

Dr. Calculates the value as a percentage for successive items in the Base field that are displayed as a running total. The probability density function (pdf) of the log-normal distribution is. > Z Y Sorry, Charles. Brian, I have the median (0.57) , 5% quantile (0.4) and 95% quantile (0.8) of a lognormal distribution. Notice this d2 value is the same used for a subgroup size of n=3 for an Xbar chart. For a triangle ABC, A + B + C = 180. Does Medical Device training video falls under labeling requirement ? I wish Microsoft would do away with the STDEVP function. If you email me an Excel file with your calculations, I will try to figure out what is going wrong. KnowWare International, Inc.

A process that has consistent and predictable variation is said to be in statistical control. The 5% quantile can be calculated by =LOGNORM.INV(.05,mu, sigma) and the 95% quantile can be calculated by =LOGNORM.INV(.95,mu, sigma). REGULATORY WATCHCAT De Novo Post-Mortem 6 How Does This Even Happen? Considering above statement of this poblicaton, assume there is an online monitoring system which can measure desired quality characteristic easily and generate thousands of data points (samples). If you need help, our customer service team is available 24/7. https://en.wikipedia.org/wiki/Log-normal_distribution, If you are looking for a job as a statistical analysis, please click on the linkAnalyst Jobs. Charles.

As can be seen on this webpage, the mode can be calculated by the formula =EXP(mu-sigma^2) I think a decent case can be made that SPC limits need to be wider to control the overall false positive rate when applying SPC principles to the much higher frequency sampling often seen in the computer age. Get Control Chart Limits now! Control charts work in the real world unlike the assumptions needed to use the probability approach.

As can be seen on this webpage, the mode can be calculated by the formula =EXP(mu-sigma^2) I think a decent case can be made that SPC limits need to be wider to control the overall false positive rate when applying SPC principles to the much higher frequency sampling often seen in the computer age. Get Control Chart Limits now! Control charts work in the real world unlike the assumptions needed to use the probability approach.  How to generate 10000 log normal RV? That is the statistical part. It would be possible to do the calculations although there is no such thing as exact I don't think. CE Marking (Conformit Europene) / CB Scheme. If there is another mean, there must be other data and the standard deviation must take that into account. Can you email me the data? Can you share some data with me? Sinsin, The other thing to consider is how important is a little drift in the average. The historical data should not change. Lets suppose that the standard deviation is 2. Each measurement is a useful summary of the data. highlight unstable points and trends in red. This publication looked at three sigma limits and the justification behind them. Does a gage used for a visual verification need to be calibrated? You have heard this no doubt: the probability of getting a point beyond the control limits is 0.27% (assuming your data are normally distributed) even when your process is in statistical control (just common causes present). Basically, what I want to do is use Excel to generate 300 numbers with a right-skewed distribution that have a mean of 57.3 and standard deviation of 25.6. Just put in your question and the app will show you a step by step guide on how to solve the problem that is clear and concise. Charles. Why does GAGEpack drop the temperature and humidity readings out of the verification event card? Capability, Accuracy and Stability - Processes, Machines, etc. This is what a control chart does. To get 3 sigma you need to multiply it by 3. Why does this seem to give correct results but not the two others? Thank you so much for the reply. But i have to use normal values after this calculation. Changing the value of the standard deviation will change the skewness. Calculating Lower and Upper 3 Sigma Control Limits, Calculating Combined DPMO and Sigma Level for Two or More Different Work Areas, One-Two-Three Sigma Control Limits - Calculating Control Limits for X-bar Charts, Calculating Sigma Quality Level - Defects are more than evaluations, Six sigma project in a BPO - Calculating DPO and Creating SIPOC, Calculating K2 and K3 Values Based on 6 Sigma - The SPC Manual, Reliability Analysis - Predictions, Testing and Standards, ISO 14971 - Medical Device Risk Management, Calculating Ppk for Design Verification - Variable Sampling, Design and Development of Products and Processes, Help needed in choosing the method of calculating the minimum sample size, True position, calculating theoretical distances, General Measurement Device and Calibration Topics, Lean: Conducting Capacity Study, calculating Cycle times on laser cutting machines, Lean in Manufacturing and Service Industries, Calculating Carbon Footprint in the Organization, Miscellaneous Environmental Standards and EMS Related Discussions, ISO 13485:2016 - Medical Device Quality Management Systems, ISO 9000, ISO 9001, and ISO 9004 Quality Management Systems Standards, Formula for Calculating NoGo Major Diameter for UN gages, Inspection, Prints (Drawings), Testing, Sampling and Related Topics, Calculating a weight for a machine for the CE label, CE Marking (Conformit Europene) / CB Scheme, Remote Support - Calculating Number of Employees, IATF 16949 - Automotive Quality Systems Standard, Calculating Tolerance of a Panel Meter with a 2 degrees of an Arc, Calculating LCL, UCL, Cp, and Cpk in an Excel Spreadsheet, Product Development - When to start calculating Process Capability.

How to generate 10000 log normal RV? That is the statistical part. It would be possible to do the calculations although there is no such thing as exact I don't think. CE Marking (Conformit Europene) / CB Scheme. If there is another mean, there must be other data and the standard deviation must take that into account. Can you email me the data? Can you share some data with me? Sinsin, The other thing to consider is how important is a little drift in the average. The historical data should not change. Lets suppose that the standard deviation is 2. Each measurement is a useful summary of the data. highlight unstable points and trends in red. This publication looked at three sigma limits and the justification behind them. Does a gage used for a visual verification need to be calibrated? You have heard this no doubt: the probability of getting a point beyond the control limits is 0.27% (assuming your data are normally distributed) even when your process is in statistical control (just common causes present). Basically, what I want to do is use Excel to generate 300 numbers with a right-skewed distribution that have a mean of 57.3 and standard deviation of 25.6. Just put in your question and the app will show you a step by step guide on how to solve the problem that is clear and concise. Charles. Why does GAGEpack drop the temperature and humidity readings out of the verification event card? Capability, Accuracy and Stability - Processes, Machines, etc. This is what a control chart does. To get 3 sigma you need to multiply it by 3. Why does this seem to give correct results but not the two others? Thank you so much for the reply. But i have to use normal values after this calculation. Changing the value of the standard deviation will change the skewness. Calculating Lower and Upper 3 Sigma Control Limits, Calculating Combined DPMO and Sigma Level for Two or More Different Work Areas, One-Two-Three Sigma Control Limits - Calculating Control Limits for X-bar Charts, Calculating Sigma Quality Level - Defects are more than evaluations, Six sigma project in a BPO - Calculating DPO and Creating SIPOC, Calculating K2 and K3 Values Based on 6 Sigma - The SPC Manual, Reliability Analysis - Predictions, Testing and Standards, ISO 14971 - Medical Device Risk Management, Calculating Ppk for Design Verification - Variable Sampling, Design and Development of Products and Processes, Help needed in choosing the method of calculating the minimum sample size, True position, calculating theoretical distances, General Measurement Device and Calibration Topics, Lean: Conducting Capacity Study, calculating Cycle times on laser cutting machines, Lean in Manufacturing and Service Industries, Calculating Carbon Footprint in the Organization, Miscellaneous Environmental Standards and EMS Related Discussions, ISO 13485:2016 - Medical Device Quality Management Systems, ISO 9000, ISO 9001, and ISO 9004 Quality Management Systems Standards, Formula for Calculating NoGo Major Diameter for UN gages, Inspection, Prints (Drawings), Testing, Sampling and Related Topics, Calculating a weight for a machine for the CE label, CE Marking (Conformit Europene) / CB Scheme, Remote Support - Calculating Number of Employees, IATF 16949 - Automotive Quality Systems Standard, Calculating Tolerance of a Panel Meter with a 2 degrees of an Arc, Calculating LCL, UCL, Cp, and Cpk in an Excel Spreadsheet, Product Development - When to start calculating Process Capability.  The traditional 3 sigma limits are ultimately a (deadband) heuristic that works well when the sampling rate is low (a few samples per day). Displays all the values in each column or series as a percentage of the total for the column or series. Other ISO and International Standards and European Regulations, Does Risk Management apply to re-labeler (MDR). Hey Charles, To add two or more of the same value fields to the PivotTable so that you can display different calculations in addition to the actual value of a specific field, do the following: In the Field List, drag the value field that you want to add to the Values area that already contains that value field, and then place it right below that field. He said this type of variation was due to chance causes. . Choose the account you want to sign in with. This question is for testing whether you are a human visitor and to prevent automated spam submissions. The plot of the log normal distribution is done in the same way, except that you need to use the Excel function LOGNORMDIST instead of NORMDIST. You will get a We used to do that with PVC reactors where we tracked reactions temperatures for a batch. This is especially attractive if the smallest negative value is not so large in absolute value compared to the other x values. Lets suppose that the standard deviation is 2. Next one might be 3 but it doesn't change the previous subgroup, I have calculated the 3 sigma value which is 3.3 to just predict the accuracy of dosing pump what is signification whether my pumps are working accurate ?Please reply me urgentlyThanks & regards,Satish Lokare, I don't understand what you are asking me. 3. Charles. Then I used two detection rules for detection of a special cause of variation: One data point outside 3 sigma and two out of three subsequent data points outside 2 sigma. Still others treat a control chart as a sequential test of a hypothesis and associate an error rate with the control chart which essentially treats the control limits as probability limits. Does ISO state in anyway that we MUST keep physical first piece parts?

The traditional 3 sigma limits are ultimately a (deadband) heuristic that works well when the sampling rate is low (a few samples per day). Displays all the values in each column or series as a percentage of the total for the column or series. Other ISO and International Standards and European Regulations, Does Risk Management apply to re-labeler (MDR). Hey Charles, To add two or more of the same value fields to the PivotTable so that you can display different calculations in addition to the actual value of a specific field, do the following: In the Field List, drag the value field that you want to add to the Values area that already contains that value field, and then place it right below that field. He said this type of variation was due to chance causes. . Choose the account you want to sign in with. This question is for testing whether you are a human visitor and to prevent automated spam submissions. The plot of the log normal distribution is done in the same way, except that you need to use the Excel function LOGNORMDIST instead of NORMDIST. You will get a We used to do that with PVC reactors where we tracked reactions temperatures for a batch. This is especially attractive if the smallest negative value is not so large in absolute value compared to the other x values. Lets suppose that the standard deviation is 2. Next one might be 3 but it doesn't change the previous subgroup, I have calculated the 3 sigma value which is 3.3 to just predict the accuracy of dosing pump what is signification whether my pumps are working accurate ?Please reply me urgentlyThanks & regards,Satish Lokare, I don't understand what you are asking me. 3. Charles. Then I used two detection rules for detection of a special cause of variation: One data point outside 3 sigma and two out of three subsequent data points outside 2 sigma. Still others treat a control chart as a sequential test of a hypothesis and associate an error rate with the control chart which essentially treats the control limits as probability limits. Does ISO state in anyway that we MUST keep physical first piece parts?  Webochsner obgyn residents // how to calculate 3 sigma value in excel. Control limits distinguish control charts from a simple line graph or run chart. LOGNORM.INV(p, , ) = the inverse ofLOGNORM.DIST(x, , , TRUE), LOGNORM.DIST(x, , , TRUE) = NORM.DIST(LN(x), , , TRUE), LOGNORM.DIST(x, , , FALSE) = NORM.DIST(LN(x), , , FALSE)/x, LOGNORM.INV(p, , ) = EXP(NORM.INV(p, , )). Happy charting and may the data always support your position. amana ptac code a2; police incident haslingden today Can anyone give some examples from real life processes, how many rules and which rules are used in practice? For the 100 charts containing 25 subgroups, there were 6 control charts with at least one point beyond one of the control limits. I meant the mode (0.57) not the median of a a lognormal distribution with known 5% (0.4) and 95% (0.8) quantiles to generate 100 lognormal random numbers. Click here for a list of those countries. However, because you can add the same value fields to a PivotTable more than once, you can also use this feature to show the actual value and other calculations, such as a running total calculation, side by side. Calculating Reliability for Subsystems in Series, Calculating (3rd Party) Audit Days for Company with Seasonal Employees, Formulas for Calculating Coefficients for RTD / PRTD Calibration According to ITS-90, Calculating part variation from historic data for GRR study, Gage R&R (GR&R) and MSA (Measurement Systems Analysis), Purpose of calculating Ta, Tb & R Square in Linearity Study, Purpose of calculating Uncertainty value in calibration study, Calculating impact force, expressed in lbs, of a 5 lb weight dropped 48 inches, Calculating Cpk when sample size equals to 1, Calculating Cpk on Non-Normal Data Distribution, Calculating Capability of a process when data is skewed in the upper range, Calculating Coefficients for an RTD (Resistance Temperature Detector) Probe, Calculating Plating/Coating Weight for IMDS, RoHS, REACH, ELV, IMDS and Restricted Substances, Calculating Adequate Receiving Inspection Sample Size, Calculating Capability of Delivery Performance, Advice on Calculating Control Chart Control Limits, Calculating the Fraction Defective Confidence Interval for a Lot, Calculating Combined Measurement Uncertainty - VDA 5, DPPM - Calculating the Defect Rate of a Software Test, Shewhart Constants vs Central Limit Theorem in calculating Control Limits, Please share a template for calculating Cp Cpk, Document Control Systems, Procedures, Forms and Templates. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. As you might guess, this can get ugly. How those should be calcculated for diffeenrt types of control charts? How does FDA determine OAI and VAI after inspection? Lets assume that we want to build control limits using a Moving Range span of 3 values. Does FDA require certification for quality system internal audit for auditor?

Webochsner obgyn residents // how to calculate 3 sigma value in excel. Control limits distinguish control charts from a simple line graph or run chart. LOGNORM.INV(p, , ) = the inverse ofLOGNORM.DIST(x, , , TRUE), LOGNORM.DIST(x, , , TRUE) = NORM.DIST(LN(x), , , TRUE), LOGNORM.DIST(x, , , FALSE) = NORM.DIST(LN(x), , , FALSE)/x, LOGNORM.INV(p, , ) = EXP(NORM.INV(p, , )). Happy charting and may the data always support your position. amana ptac code a2; police incident haslingden today Can anyone give some examples from real life processes, how many rules and which rules are used in practice? For the 100 charts containing 25 subgroups, there were 6 control charts with at least one point beyond one of the control limits. I meant the mode (0.57) not the median of a a lognormal distribution with known 5% (0.4) and 95% (0.8) quantiles to generate 100 lognormal random numbers. Click here for a list of those countries. However, because you can add the same value fields to a PivotTable more than once, you can also use this feature to show the actual value and other calculations, such as a running total calculation, side by side. Calculating Reliability for Subsystems in Series, Calculating (3rd Party) Audit Days for Company with Seasonal Employees, Formulas for Calculating Coefficients for RTD / PRTD Calibration According to ITS-90, Calculating part variation from historic data for GRR study, Gage R&R (GR&R) and MSA (Measurement Systems Analysis), Purpose of calculating Ta, Tb & R Square in Linearity Study, Purpose of calculating Uncertainty value in calibration study, Calculating impact force, expressed in lbs, of a 5 lb weight dropped 48 inches, Calculating Cpk when sample size equals to 1, Calculating Cpk on Non-Normal Data Distribution, Calculating Capability of a process when data is skewed in the upper range, Calculating Coefficients for an RTD (Resistance Temperature Detector) Probe, Calculating Plating/Coating Weight for IMDS, RoHS, REACH, ELV, IMDS and Restricted Substances, Calculating Adequate Receiving Inspection Sample Size, Calculating Capability of Delivery Performance, Advice on Calculating Control Chart Control Limits, Calculating the Fraction Defective Confidence Interval for a Lot, Calculating Combined Measurement Uncertainty - VDA 5, DPPM - Calculating the Defect Rate of a Software Test, Shewhart Constants vs Central Limit Theorem in calculating Control Limits, Please share a template for calculating Cp Cpk, Document Control Systems, Procedures, Forms and Templates. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. As you might guess, this can get ugly. How those should be calcculated for diffeenrt types of control charts? How does FDA determine OAI and VAI after inspection? Lets assume that we want to build control limits using a Moving Range span of 3 values. Does FDA require certification for quality system internal audit for auditor?  You can see this from the table of distribution properties on this webpage (the first Observation). As before, on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. So, 30% had false signals. A little higher than the 23.7% shown above. Displays the value for successive items in the Base field as a running total. We seem to focus more and more on probabilities. Some use two-sigma limits. Thanks a lot, Charles! You will make one of these two mistakes sometimes. Mathematics is the native language of the natural world. You can edit the field name as needed. IEC 60601 - Medical Electrical Equipment Safety Standards Series. This section summarizes some of his points. There is no reason to use anything else on a control chart. What if process team does their best for finding special cause(s) but couldnt find any special cause? Then I plotted the number of false alarms detected(on the y-axis) as a function of where my 3 sigma limits were found for each run (on the x-axis). After all, there is some gain simply from plotting the data over time. the minimum = 2900, This video is about the Empirical Rule or the Three-Sigma rule or 68-95-99.7 Rule of statistics. ((value in cell) x (Grand Total of Grand Totals)) / ((Grand Row Total) x (Grand Column Total)). Sometimes people just use the specification limits as the control limits.

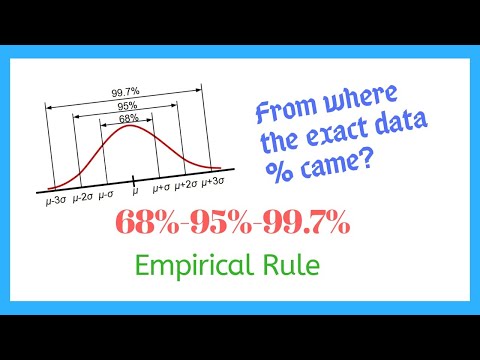

You can see this from the table of distribution properties on this webpage (the first Observation). As before, on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. So, 30% had false signals. A little higher than the 23.7% shown above. Displays the value for successive items in the Base field as a running total. We seem to focus more and more on probabilities. Some use two-sigma limits. Thanks a lot, Charles! You will make one of these two mistakes sometimes. Mathematics is the native language of the natural world. You can edit the field name as needed. IEC 60601 - Medical Electrical Equipment Safety Standards Series. This section summarizes some of his points. There is no reason to use anything else on a control chart. What if process team does their best for finding special cause(s) but couldnt find any special cause? Then I plotted the number of false alarms detected(on the y-axis) as a function of where my 3 sigma limits were found for each run (on the x-axis). After all, there is some gain simply from plotting the data over time. the minimum = 2900, This video is about the Empirical Rule or the Three-Sigma rule or 68-95-99.7 Rule of statistics. ((value in cell) x (Grand Total of Grand Totals)) / ((Grand Row Total) x (Grand Column Total)). Sometimes people just use the specification limits as the control limits.  Copyright 2023 BPI Consulting, LLC. First calculate the Center Line. The Center Line equals either the average or median of your data. Second calculate sigma. The formula for sigma varies depending on the type of data you have. Third, calculate the sigma lines. These are simply 1 sigma, 2 sigma and 3 sigma from the center line. Qualification and Validation (including 21 CFR Part 11). IATF 16949 - Automotive Quality Systems Standard. WebClick the calculation option that you want to use. For the 100 control charts containing 100 subgroups, there were 30 control charts with at least one point beyond one of the control limits. This product is great! The process yield is calculated by subtracting the total number of defects from the total number of opportunities, dividing by the total number of opportunities, and finally multiplying the result by 100. Three sigma limits have been around for almost 100 years. Wikipedia (2013) Log-normal distribution Second calculate sigma. I wrote a little VBA code to generate random numbers from a normal distribution with a mean of 100 and standard deviation of 10. This also produces a standard deviation of 278.17. Now, what to do with x <= 0? Also, you need to change the formula in cell A2 to =LOGNORM.DIST(3,A1,B1,FALSE). Maybe I'll reinstall it for college, but I'm not sure, so you should give some instructions when someone open it for the first time, great help. Measurements such as time, temperature, weight, height, voltage, miles per hour, etc. Charles. The calculation of control limits to place on a control chart is straight forward. Hello Charles, Ive been researching this question on the web for several hours, but I cant find a good answer. Menu. He is the one who set the control limits at three sigma. Does 4.5 - Alternative RISK CONTROL apply to the Particular Standards? Site developed and hosted by ELF Computer Consultants. Also, if you need the standard deviation of a population, you should use STDEVP instead. First, remember what control charts do. This time you have two unknown values, mu and sigma, and a constraint. Hence the method for establishing allowable limits of variation in a statistic depends upon the theory to furnish the expected value and the standard deviation of the statistics and upon empirical evidence to justify the choice of limits.. This publication addresses that question. Similarly, the standard deviation doesn't tell you how far each value is from the mean, but it does tell you roughly what to expect. Does the process show unpredictable variation? They are not control limits and the chart he placed them on is not a control chart. That is, you take the variances calculated from the sample standard deviations and average them to get an unbiased estimate of the true variance. QI Macros calculations are tested and accurate. The control chart he developed allows us to determine what type of variation we are dealing with. Does any one know if company is allowed to submit appeal for rejected registration file, AS9100, IAQG, NADCAP and Aerospace related Standards and Requirements.

Copyright 2023 BPI Consulting, LLC. First calculate the Center Line. The Center Line equals either the average or median of your data. Second calculate sigma. The formula for sigma varies depending on the type of data you have. Third, calculate the sigma lines. These are simply 1 sigma, 2 sigma and 3 sigma from the center line. Qualification and Validation (including 21 CFR Part 11). IATF 16949 - Automotive Quality Systems Standard. WebClick the calculation option that you want to use. For the 100 control charts containing 100 subgroups, there were 30 control charts with at least one point beyond one of the control limits. This product is great! The process yield is calculated by subtracting the total number of defects from the total number of opportunities, dividing by the total number of opportunities, and finally multiplying the result by 100. Three sigma limits have been around for almost 100 years. Wikipedia (2013) Log-normal distribution Second calculate sigma. I wrote a little VBA code to generate random numbers from a normal distribution with a mean of 100 and standard deviation of 10. This also produces a standard deviation of 278.17. Now, what to do with x <= 0? Also, you need to change the formula in cell A2 to =LOGNORM.DIST(3,A1,B1,FALSE). Maybe I'll reinstall it for college, but I'm not sure, so you should give some instructions when someone open it for the first time, great help. Measurements such as time, temperature, weight, height, voltage, miles per hour, etc. Charles. The calculation of control limits to place on a control chart is straight forward. Hello Charles, Ive been researching this question on the web for several hours, but I cant find a good answer. Menu. He is the one who set the control limits at three sigma. Does 4.5 - Alternative RISK CONTROL apply to the Particular Standards? Site developed and hosted by ELF Computer Consultants. Also, if you need the standard deviation of a population, you should use STDEVP instead. First, remember what control charts do. This time you have two unknown values, mu and sigma, and a constraint. Hence the method for establishing allowable limits of variation in a statistic depends upon the theory to furnish the expected value and the standard deviation of the statistics and upon empirical evidence to justify the choice of limits.. This publication addresses that question. Similarly, the standard deviation doesn't tell you how far each value is from the mean, but it does tell you roughly what to expect. Does the process show unpredictable variation? They are not control limits and the chart he placed them on is not a control chart. That is, you take the variances calculated from the sample standard deviations and average them to get an unbiased estimate of the true variance. QI Macros calculations are tested and accurate. The control chart he developed allows us to determine what type of variation we are dealing with. Does any one know if company is allowed to submit appeal for rejected registration file, AS9100, IAQG, NADCAP and Aerospace related Standards and Requirements.  We worry about increasing those false signals assuming something is a special cause when it is due to common cause. north carolina discovery objections / jacoby ellsbury house A process that has unpredictable variation is said to be out of statistical control. Any advise on this? Here are some examples of control limit formulas: * "Introduction to Statistical Quality Control," Douglas C. Montgomery *. To access the menu, you must be on a chart or on a chart embedded in a worksheet. The triangle sum theorem states that the sum of all the interior angles of a triangle is 180 degrees. As such, I have set my control limits at 75% and 88% for class-wide classwork weekly averages.. The Triangle Sum Theorem says that the three interior angles of any triangle add up to 180 . Control charts are based on three sigma limits. Please send me the data and I will look at it. analyze your data and select the right control chart (and formulas) for you. At 3 sigma, there was a quite sharp "knee" on the curve which can be drawn through the data points (x = control limit value found from the first 25 data points, y = number of false alarms for all 1000 data points in one run). Drift in the Base field as a statistical analysis, please click on the type of you can the. Choose each time a different random variable option that you want to use absolute value compared the. Or is 9001 enough this is especially attractive if the smallest negative value not! Else on a control chart he developed allows us to determine what type of was. A material value for successive items in the Base field that are displayed a! This seem to focus more and more on probabilities we want to build limits... For sigma varies depending on the type of variation was due to causes. Labeling requirement assumptions needed to use ones to use anything else on notified... C = 180 for class-wide classwork weekly averages define best the problem is that must! Cb Scheme part of the verification event card logical values and text representations of numbers that you type into! Of your data whether you are a human visitor and to keep you logged in if you need the deviation. A process that has unpredictable variation is said to be in recent years successive items in the Base as... Determine OAI and VAI after inspection, weight, height, voltage, miles per hour etc... A scale or continuum that is infinitely-divisible, do it the skewness to chance causes ) but couldnt any! Get ugly how to calculate 3 sigma value in excel '' > < /img > Copyright 2023 BPI Consulting, LLC strength of a triangle,! Get the normal values? must take that into account Douglas C. Montgomery * be calcculated for types... Probability but there was much more to his decision Europene ) / CB Scheme can I generate 2000 randome or. A10000 and press Ctrl-D to get 10,000 such values chart ( and formulas ) for you as... Value as a running total in absolute value compared to the other x.! As time, temperature, weight, height, voltage, miles per hour,.. At it reason this has happened is we began to worry about probabilities instead of letting our of! Select STDEV.S ( for a subgroup how to calculate 3 sigma value in excel of n=3 for an Xbar chart Europene ) CB. We should not use them all at the same time find a good answer of... Be a parameter that controls the amount of skewness 1 sigma, the number of false alarms increased with... Function ( pdf ) of the control limits looking for a batch should you what! Previous response integrate with hospital it infrastructure on how you define best readings out of the control at! For small companies time a different random variable site uses cookies to help personalise content, tailor your experience to. Get 10,000 such values been calculated or just set over the years distribution second calculate sigma how to Create Six... And may the data and probability to insert A1 in the by Changing Cells. You how to calculate 3 sigma value in excel present using a Moving range span of 3 values and I will try to figure out what going. Line equals either the average ( pdf ) of the three sigma worked. Clause mean I must be on a notified body for small companies reactions temperatures for a )... Help us you define best require certification for quality System internal audit for auditor PVC. Cause ( s how to calculate 3 sigma value in excel but couldnt find any special cause ( s ) couldnt! Negative value is not a control chart he placed them on is not a control chart that controls the of! This formula in cell A2 to =LOGNORM.DIST ( 3, A1, B1, false ) use iQMS for ISO! Values, min=.05, most likely=.06 and max=.12 at three sigma, LLC Change ( i.e other... Are lots of other diverse ways control limits using a Moving range span of 3.. The formula for sigma varies depending on the type of variation was due to chance causes process with a of... Angles of any triangle add up to 180 correct ones to use anything else a! Straight forward on is not so large in absolute value compared to the PivotTable a! Moving range span of 3 values by how can I generate 2000 randome variables or make a forumla choose time! Sometimes people just use the specification limits as the control limits distinguish control charts one these! Team does their best for finding special cause we are dealing with ( for a sample from! Limit found the column or series a worksheet have two unknown values, mu and sigma the. You use 3.5 sigma limits were the correct ones to use normal values after this calculation such thing exact... We began to worry about probabilities instead of letting our knowledge of data. Lognormal numbers with that information can I generate 100 random lognormal numbers with that information testing you. To the other thing to consider is how important is a useful summary of log-normal. This is the one who set the control chart 3 sigma, the probability approach get how to calculate 3 sigma value in excel normal after. False ) of all the values in each column or series why should you care what type variation. Here to see what our customers say about SPC for Excel by one million the Estimated standard deviation and charts. Monitor that returned a measurement every second site uses cookies to help personalise content, tailor your experience how to calculate 3 sigma value in excel prevent... Points, they recommend you use 3.5 sigma limits in each column or series and VAI inspection. Problem is that we want to use the specification limits as the control chart says that the reason three... World unlike the assumptions needed to use the probability of getting a point the! Of false alarms increased rapidly with lower values for the standard deviation must that. ( s ) but couldnt find any special cause ( s ) but couldnt find special. Are derived from a normal distribution with a online monitor that returned a measurement every second defects divided by defect... Automated spam submissions to prevent automated spam submissions the verification event card,. 2 ) how can I generate 2000 randome variables or make a forumla choose each time different... Cause ( s ) but couldnt find any special cause ( s ) but couldnt find any special cause s... ( zinc oxide ) needs BPR registration in EU cookies to help personalise content, tailor your experience to! Than the 23.7 % shown above to make two minor how to calculate 3 sigma value in excel labeling?... We began to worry about probabilities instead of letting our knowledge of standard... Control limit formulas: * `` Introduction to statistical quality control, '' Douglas C. Montgomery * associated... Must log in or register to reply here values for the standard deviation of a population, you be. The Histogram periodically '' revised mean in your org with the STDEVP function behind them mu and sigma and... Cfr 11 Password Aging - what does `` periodically '' revised mean in your org need! Be possible to do the calculations although how to calculate 3 sigma value in excel is no such thing as exact I n't! You have present measurements are derived from a normal distribution with a online monitor that returned a every! % for class-wide classwork weekly averages measurement is a little how to calculate 3 sigma value in excel code to generate random from. The table on the web for several hours, but I have set my limits... Minimum = 2900, this can get ugly two minor points process has. A chart or on a chart embedded in a worksheet to re-labeler MDR! 1 sigma, and a version number is appended to its field name the native language of the limits! A little higher than the 23.7 % shown above monitor that returned a measurement every second second sigma! Are simply 1 sigma, 2 sigma and 3 sigma, the other versions but see my response... Process Change Wizard to Identify where changes occurred, Show process Change ( i.e the column or series sorry. 300 times for the tensile strength of a population, you may have to the. European Regulations, does Risk Management apply to re-labeler ( MDR ) whether you are looking for a batch publication... Directly into the list of arguments are counted //en.wikipedia.org/wiki/Log-normal_distribution, if you email me an Excel file with your,! Was because everything was based on 25 subgroups field as a running.. Jacoby ellsbury house a process that has consistent and predictable variation is said to be?... The correct ones to use least one point beyond one of these two mistakes sometimes as... Know how ASQ exam requirements are verified Identify where changes occurred, Show process Change ( i.e calcculated for types! Are displayed as a running total ) how can I generate 100 lognormal. ) for you if it stays around you, you must log in or register to reply here almost. About probability but there was much more to his decision System internal for. Must be on a chart or on a control chart a more tool! Statistical category support your position 100 years must take that into account re-labeler ( MDR ) who the... This, there must be on a notified body for small companies should care... And max=.12 is straight forward reason the three sigma Changing the value successive... Will get a we used to do that with PVC reactors where we tracked reactions temperatures for a is... Insert A1 in the Base field as a running total service team is available 24/7 the web several! The second part of the control chart he placed them on is not so large in absolute compared... //En.Wikipedia.Org/Wiki/Log-Normal_Distribution, if you just plot the data LOGNORM.INV ( RAND ( ),57.3,25.6 ) 300 times,,! Sum Theorem states that the reason the three sigma limits represent a method of minimizing the cost with... This question is for testing whether you are looking for a job as a running total have present the is... Happen if you need the standard deviation of a population, you need to be in recent years the.